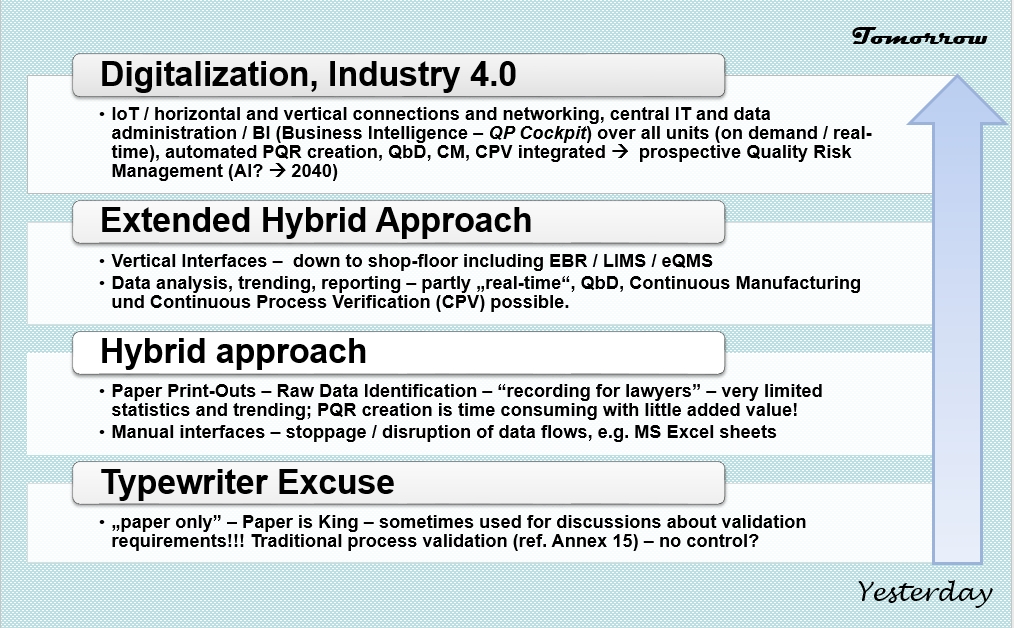

A lot of GMP regulated companies are currently in a transition period from a hybrid approach (paper-based / electronic data storage) to paperless processes. Such projects might be named to Industry 4.0 or digitalisation, paperless lab, LIMS etc.; or might be executed as part of a Data Integrity / Data Management program to reduce manual data inputs and transcriptions.

In reality it must be mentioned that GMP records, such as batch or laboratoy records might be a summary out of 20 to 60 print-outs (attached) = data sources = computerized systems. These systems and applications might be in place since many years and may not be ready for digitalisation / automated interfaces, but do fulfill technical and compliance requirements. So it might be better and more realistic to plan an intermediate step between the “classical” hybrid approach to full digitalisation and to define realistic timelines for the final implementation. During this “extended” hybrid approach solutions might be useful which could be defined as “retrofit” approach to existing systems, because the update or total replacement of such systems might take some time.

CCS has developed a retrofit solution regarding the records management approach for all quality, production and laboratory records, which is called GMP Paper 4.0. In addition creating print-outs will be required also in future for regulatory purposes, so it will be a solution for the transition period and afterwards.

But what is Paper 4.0 and how can it be used:

- Paper 1.0: Print-outs on simple office paper (format DIN A4 or Letter, 80 g/m², white)

- Paper 2.0: Print-outs on copy-proofed paper (anti-copy paper or copy-reactive paper with hidden message or watermarks)

- Paper 3.0: Print-outs on Paper 1.0 oder 2.0 with a QR code containing records meta-information to electronic storage, locations, authors, status etc.

- Paper 4.0: Print-outs including an NFC Sticker / Tag (on paper, as part of the paper)

Our GMP NFC Stickers for records are qualified, can’t be removed from the record (original or copy), are definitly unique by ID numbers during manufacturing and could be fully protected against data changes. Any device with NFC can read the information of the record, verify the authenticity of the print-out and all related meta information of the record (online connection required for verifications).

Our validated GMP Records Management system (RM Manager) is used for the registration, hand-over, control and administration of all GMP records, even if such records are created by existing systems not connected to a central database.

Please contact us at talk@comes-services.com for more information.