Question #3 of the Q&A section:

How do the Part 11 regulations and “predicate rule requirements” (in 21 CFR Part 211) apply to the electronic records created by computerized laboratory systems and the associated printed chromatograms that are used in drug manufacturing and testing?

Some in industry misinterpret the following text from “The Guidance for Industry – Part 11, Electronic Records; Electronic Signatures – Scope and Application” (Part 11 Guidance; lines 164 to 171) to mean that in all cases paper printouts of electronic records satisfy predicate rule requirements in 21 CFR Part 211.

“Under the narrow interpretation of the scope of part 11, with respect to records required to be maintained under predicate rules or submitted to FDA, when persons choose to use records in electronic format in place of paper format, part 11 would apply. On the other hand, when persons use computers to generate paper printouts of electronic records, and those paper records meet all the requirements of the applicable predicate rules and persons rely on the paper records to perform their regulated activities, FDA would generally not consider persons to be ‘using electronic records in lieu of paper records’ under §§ 11.2(a) and 11.2(b). In these instances, the use of computer systems in the generation of paper records would not trigger part 11.”

The Part 11 Guidance also states (in lines 150-152), that:

“…persons must comply with applicable predicate rules, and records that are required to be maintained or submitted must remain secure and reliable in accordance with the predicate rules.”

For High Performance Liquid Chromatography (HPLC) and Gas Chromatography (GC) systems (and other computerized systems involving user inputs, outputs, audit trials, etc.), the predicate rules, such as 21 CFR 211.68 and 21 CFR 211.180(d), require the electronic records themselves to be retained and maintained in accordance with those regulations. 21 CFR 211.180(d) requires records to be retained “either as original records or true copies such as photocopies, microfilm, microfiche, or other accurate reproductions of the original records.” 21 CFR 211.68 further states that: “[H]ard copy or alternative systems, such as duplicates, tapes, or microfilm, designed to assure that backup data are exact and complete and that it is secure from alteration, inadvertent erasures, or loss shall be maintained” (emphasis added). The printed paper copy of the chromatogram would not be considered a “true copy” of the entire electronic raw data used to create that chromatogram, as required by 21 CFR 211.180(d). The printed chromatogram would also not be considered an “exact and complete” copy of the electronic raw data used to create the chromatogram, as required by 21 CFR 211.68. The chromatogram does not generally include, for example, the injection sequence, instrument method, integration method, or the audit trail, of which all were used to create the chromatogram or are associated with its validity. Therefore, the printed chromatograms used in drug manufacturing and testing do not satisfy the predicate rule requirements in 21 CFR Part 211. The electronic records created by the computerized laboratory systems must be maintained under these requirements.

We recognize that there are cases where it could be appropriate for the printed chromatogram to be used within laboratories for the review of test results. Similarly, it also may be acceptable to provide the printed chromatogram during a regulatory inspection or for application review purposes. However, the electronic record must be maintained and readily available for review by, for example, QC/QA personnel or the FDA investigator.

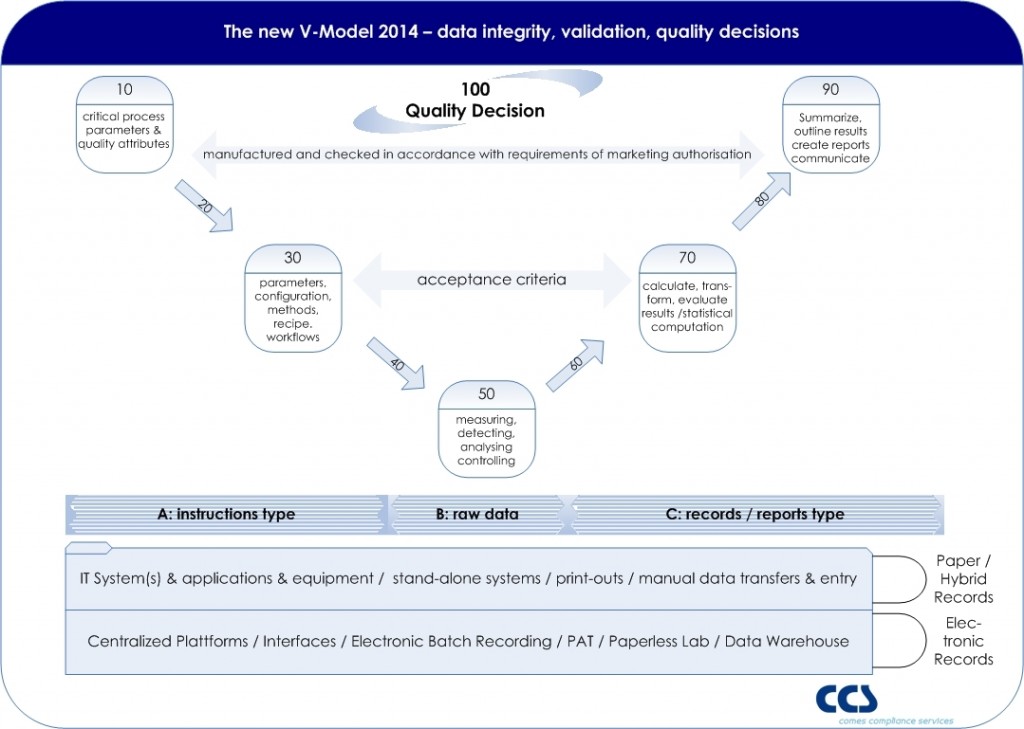

In summary, decisions on how to maintain records for computerized systems should be based on predicate rule requirements. We recommend that these decisions be supported by a sound risk assessment.

References:

• Guidance for Industry – Part 11, Electronic Records; Electronic Signatures – Scope and Application ( http://www.fda.gov/cder/guidance/5667fnl.pdf )

• 21 CFR 211.180(d): General Requirements

• 21 CFR 211.68: Automatic, Mechanical, and Electronic Equipment

Source: http://www.fda.gov/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/ucm124787.htm

Want to know more about raw data, master data and meta data management for GMP compliance?

Contact us at: talk@comes-services.com